Two stroke engine spare parts reconditioning

The scope of regeneration for marine two stroke engine spare parts supplied by MSS Motor Ship Service includes:

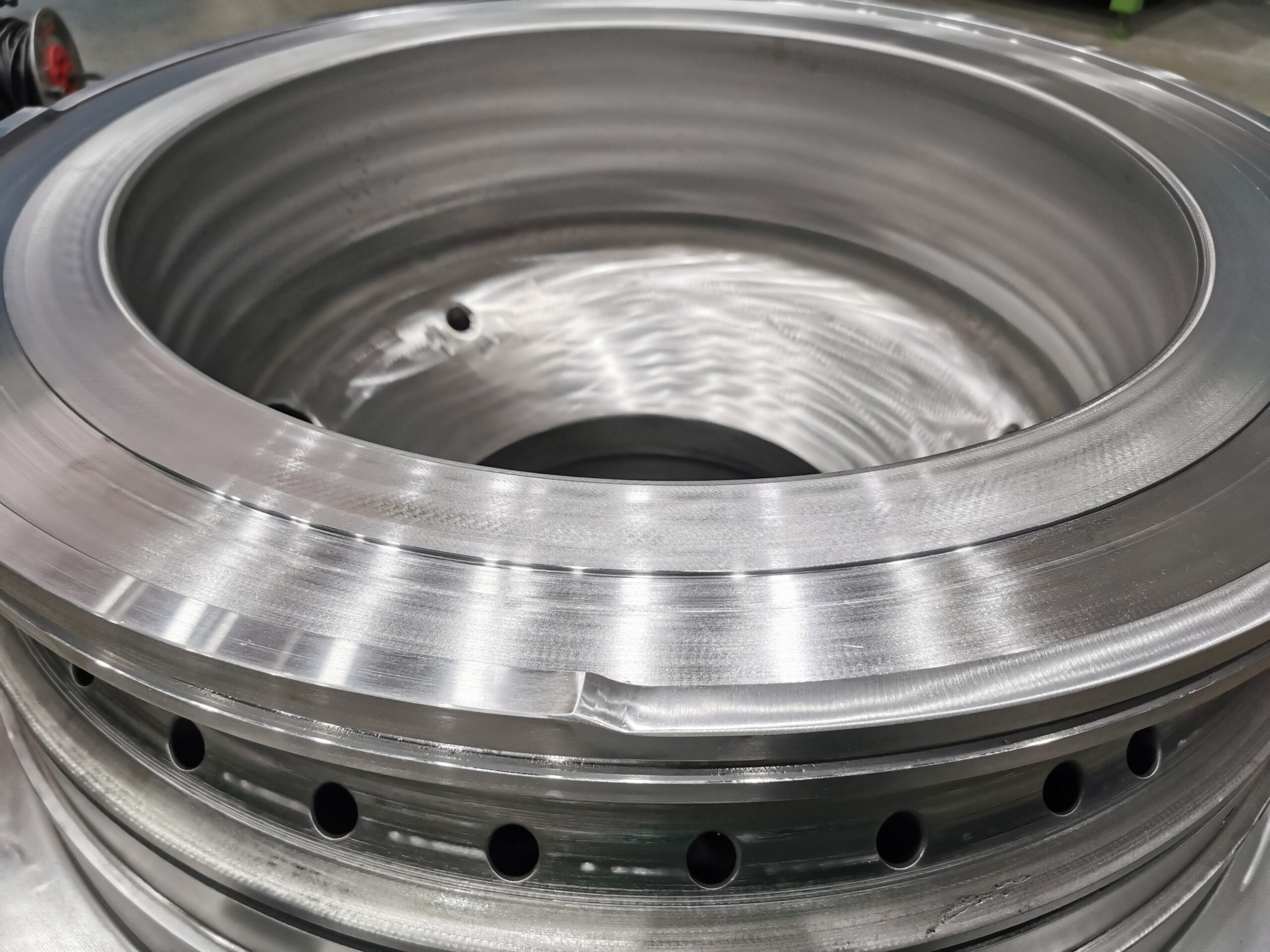

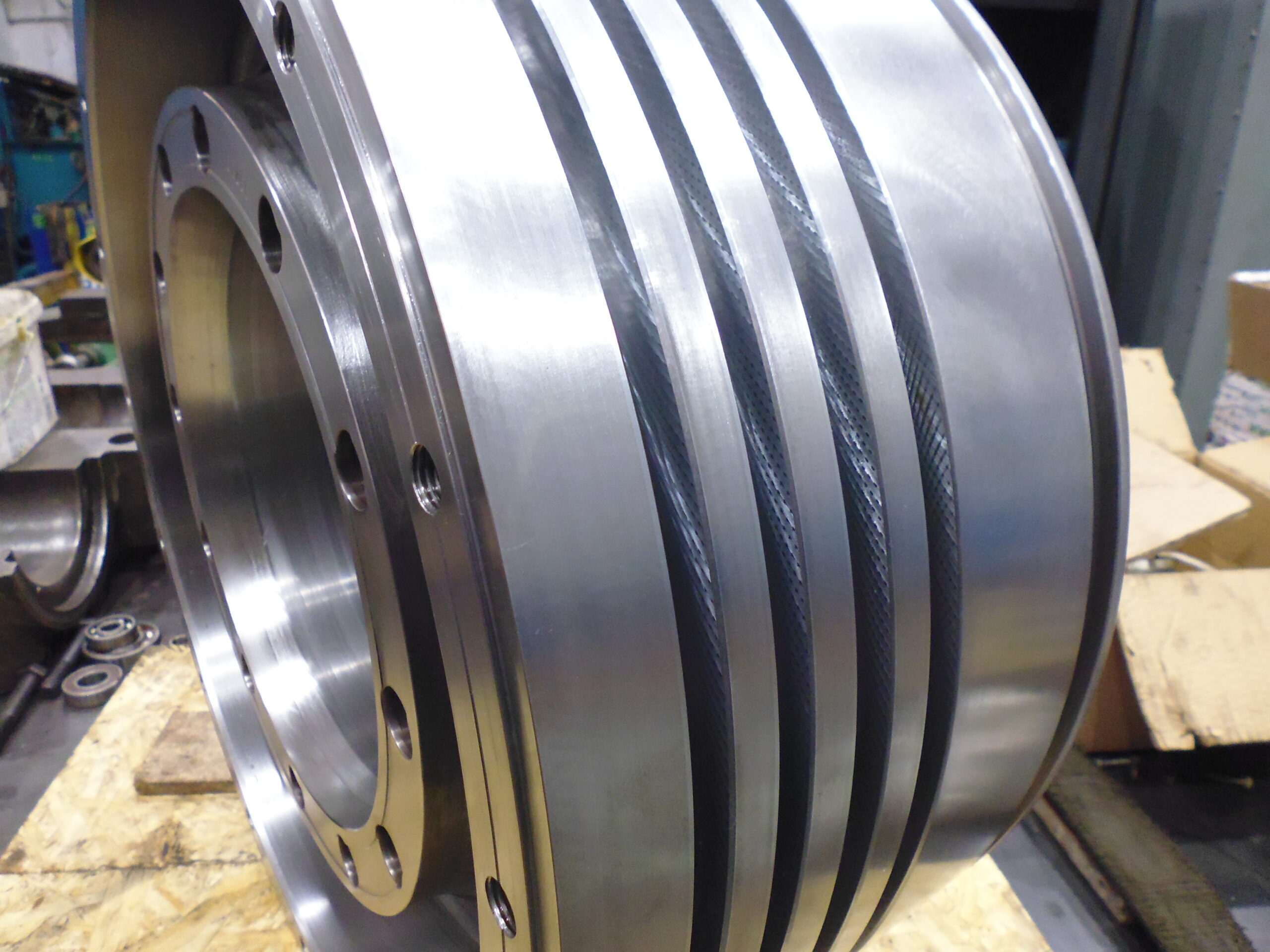

• cylinder covers,

• jackets,

• piston crowns,

• piston skirts,

• exhaust valve spindles,

• housing,

• exhaust valve seats,

• cylinder liners,

from producers such as MAN, Holeby, Hyundai, Hanshin, B&W, MaK, Wartsila/Sulzer, ex. Stork, Yanmar, Deutz, Mitsubishi, Mitsui, Pielstick, ABB etc.

We have a stock of reconditioned spare parts of marine two-stroke engine in our warehouse in Poland (Gdansk/Zielona Góra), including MAN B&W, Mitsubishi and Sulzer, Deutz etc. which may be send directly on board or elsewhere immediately in case of emergency situation/ unexpected repair or overhaul. Please check “spares from stock” and do not hesitate to contact us if there is no spare part you are interested in on the list – the list is currently updated.