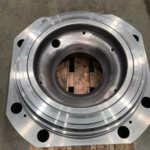

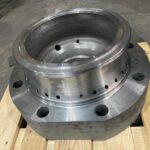

Cylinder covers may be regenerated in few options, partially or fully depending on the damages found what allows for time and budget savings. The cylinder heads are regenerated by machining, welding and normalization after the whole process.

Our technology and experience of our specialist allows for:

• Full regeneration of corroded elements to nominal values,

• Chamber cracks repair which came from overheating or unproper previous regeneration,

• Cooling jackets repair/regeneration – cracks are repaired by welding or metal stitching

• Water cooling area full regeneration,

• All damaged contact surfaces rewelding and machining for nominal value,

• Exhaust valve seat place (contact surface/bore) rewelding and machining for nominal dimensions,

• Injectors seats regeneration, starting valve connection to the chamber repair if broken,

• All threads reconditioning, if damaged